Quality and Capability

Hartridge uses state-of-the art facilities and processes in our R&D, manufacturing and production. This enables us to offer testing equipment of the highest quality.

Hartridge uses state-of-the art facilities and processes in our R&D, manufacturing and production. This enables us to offer testing equipment of the highest quality.

Located in Buckingham in the heart of the UK, Hartridge occupies a purpose-built facility of approximately 27,000 ft2 (2500 m2) that is used for our state-of-the-art production, R&D and administration. Our products are produced

here for worldwide distribution.

Our Buckingham headquarters is supplemented by around 85 distributors globally, who are considered to be extensions of the Hartridge organisation.

Hartridge has invested in advanced production control systems and state-of-the-art project management systems allowing better workflow and control of production. Assembly areas for products are arranged to cope with both serial production and one-off assembly and test, and are closely linked to our stores and tool room.

Hartridge owes its success to innovation, and innovation holds the key to our future. Research and development is undertaken in a silo, but is firmly based on the real present and future needs of each individual market.

The Hartridge production engineering team keeps a watchful worldwide eye on the development of new production technologies and techniques. Highly responsive, they are quick to invest whenever an opportunity presents itself to further improve product quality and cut production costs.

Our product range offers both All-Makes coverage and authorised testing. Our OE heritage and partnerships with OEMs mean that a number of our test benches carry authorisation for official workshops.

Our non-authorised solutions, or All-Makes products, also deliver considerable coverage and advanced testing for a comprehensive solution for non-authorised workshops.

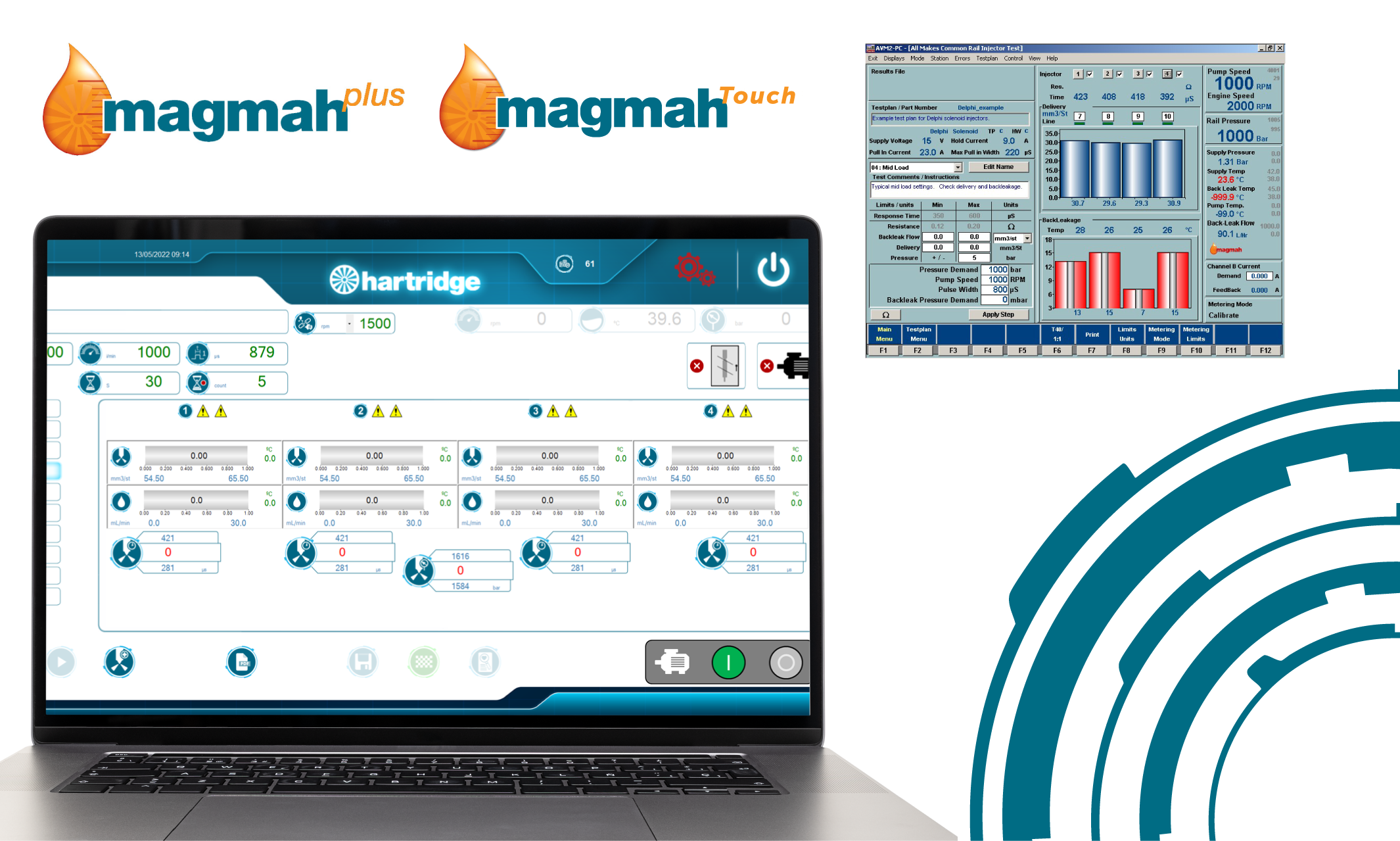

The majority of our products are operated by the powerful magmahTouch software. magmah has gone through many iterations, in keeping with the latest technology, to now be an intuitive interface with your Hartridge machine.

With flexible licensing options, free-of-charge updates and free-of-charge cloud backup, the current magmahTouch software is everything a piece of modern test equipment should be.

Our contracts are strictly organised on a project basis, with R&D specialists working closely with our engineers who will build prototypes and initiate modifications needed to reduce manufacturing and in-service costs.

Considerable time and money are invested to ensure Hartridge products meet the highest standards of performance and reliability over a long operating life. This ensures that all of our customers enjoy the best possible returns on their investments.

Have a question or need any more information? Contact our team to provide the solutions you need.